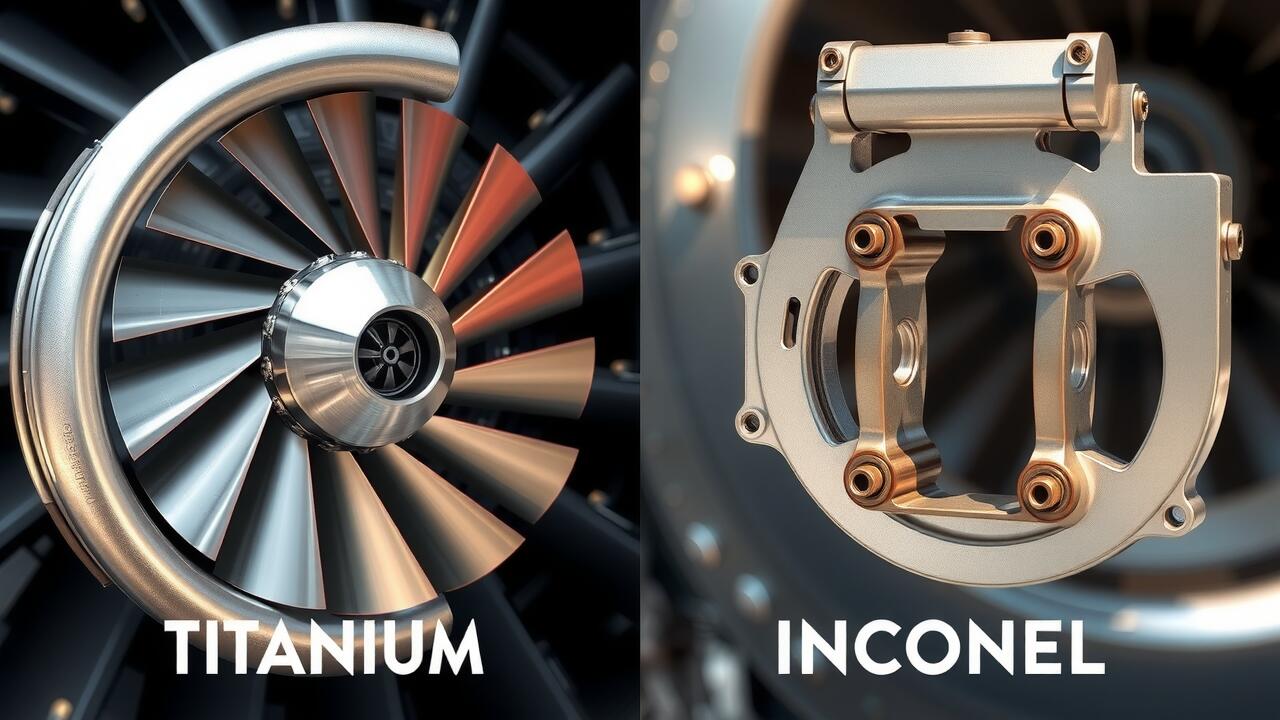

Expert Analysis: The Metallurgical Trade-Offs of Titanium vs. Inconel in Aerospace Components

Heat Resistance and Performance

Temperature tolerance plays a critical role in the design and functionality of aerospace components. Components in jet engines, for example, can encounter temperatures exceeding 1,600°F (871°C). Under such conditions, Inconel, known for its high heat resistance, maintains structural integrity while titanium's performance can degrade due to its lower melting point. This distinction can dictate the selection of materials for specific applications, especially in environments where thermal cycling occurs frequently.

The demand for precision in aerospace machining emphasizes the need for optimal material choices. An aerospace machining company often balances the advantages of titanium, such as its excellent strength-to-weight ratio, against the heat-resistant properties of Inconel. According to research, Inconel retains about 70% of its strength even at elevated temperatures, while titanium can lose significant durability above its threshold. Selecting the right material not only ensures reliability but also complies with stringent industry regulations, enhancing safety and performance outcomes in aerospace applications.

How Can Temperature Tolerance Impact Component Design?

Temperature tolerance plays a crucial role in the design of aerospace components. Materials like titanium and Inconel exhibit different thermal properties, significantly influencing their application in high-stress environments. Titanium demonstrates excellent strength-to-weight ratios at elevated temperatures, maintaining structural integrity up to approximately 600°F. Conversely, Inconel withstands much higher thermal ranges, withstanding temperatures exceeding 2,000°F while resisting oxidation and corrosion. Such characteristics necessitate careful consideration during the engineering process, particularly in critical components like engine casings or turbine blades, where thermal cycles directly affect performance and longevity.

The impact of temperature tolerance on component design extends beyond material selection. Aerospace machining methods must accommodate the thermal expansion rates of chosen alloys, necessitating precise tolerances during manufacturing. For example, CNC aerospace machining techniques can optimize the shaping of titanium to account for its lower thermal stability during machining processes, while Inconel may require slower machining speeds due to its toughness. Adhering to industry standards, such as those set by the Aerospace Industries Association, ensures that components manufactured are suitable for their intended high-temperature applications. Understanding these distinctions aids engineers and designers in developing robust components that meet rigorous performance expectations.

Mechanical Properties Compared

Titanium and Inconel exhibit distinct mechanical properties, making them uniquely suitable for varied applications within aerospace components. Titanium is known for its lightweight nature and excellent strength-to-weight ratio. This property is particularly valuable in aerospace machining where reducing weight without compromising strength is crucial. Conversely, Inconel boasts superior tensile strength and yields significant performance enhancements at elevated temperatures. For instance, Inconel 625 can maintain structural integrity at operating temperatures upwards of 1800°F, making it ideal for components exposed to extreme thermal environments.

Evaluating mechanical properties involves scrutinizing specific metrics such as tensile strength, yield strength, elongation, hardness, and fatigue resistance. A comparison shows that Inconel typically surpasses titanium in tensile strength, with values often exceeding 100,000 psi for Inconel 718. In contrast, commercially pure titanium would generally have a tensile strength of around 60,000 psi. This strength differential directly influences component design, particularly in applications requiring robust performance under stress, such as turbine blades or exhaust systems. Aerospace machining companies can leverage these insights to optimize material selection, ensuring components meet stringent aerospace standards while maintaining operational efficiency.

5 Key Metrics for Evaluating Performance

Evaluating the performance of titanium and Inconel in aerospace components hinges on several critical metrics. Tensile strength is a primary parameter; titanium alloys typically exhibit tensile strengths ranging from 900 to 1300 MPa, while Inconel 625 can reach strengths of 800 to 1100 MPa. This distinction impacts the load-bearing capacity in aerospace applications. Additionally, fatigue resistance plays a significant role since components often endure cyclic loading. Titanium, specifically Titanium 6Al-4V, shows superior fatigue resistance compared to many Inconel alloys, making it favorable for dynamic aerospace environments.

Corrosion resistance is another essential factor that can’t be overlooked. Both materials exhibit remarkable resistance in various environments, yet Inconel’s nickel content provides enhanced resistance to oxidation at high temperatures, often leading specific applications to favor it. Furthermore, density represents a vital consideration; titanium is approximately 40% lighter than Inconel, which can yield substantial weight savings in aircraft design. This reduced weight directly influences fuel efficiency, an increasingly important metric in aerospace machining. The synergy of these evaluations assists aerospace machining companies in determining material selection for critical structural components.

Joining Techniques and Compatibility

Welding techniques for titanium and Inconel require specific considerations due to their distinct thermal and chemical properties. For instance, titanium readily absorbs impurities, making inert gas shielding critical during the welding process. Processes like Gas Tungsten Arc Welding (GTAW) are frequently used with titanium, ensuring a clean environment to prevent contamination. Conversely, Inconel, known for its exceptional high-temperature strength and oxidation resistance, often employs methods such as Electron Beam Welding (EBW) and Shielded Metal Arc Welding (SMAW). Selecting the right technique not only preserves the integrity of the materials but also enhances component durability and reliability in aerospace applications.

Compatibility between titanium and Inconel presents additional challenges, particularly in multi-material assemblies common in aerospace projects. A CNC aerospace machining company must carefully evaluate thermal expansion coefficients, as the dissimilar behaviors of these metals under heat can lead to joint failures. For optimal performance, engineers prefer employing filler materials that offer adequate bonding without adverse reactions. A case study involving aerospace components demonstrated the success of tailored alloy fillers, enabling robust joint formations while minimizing stress concentrations. Adhering to standards such as ASTM E2657 can guide practitioners in selecting appropriate welding methods and materials, ensuring long-lasting and reliable joint performance.

What Are the Best Methods for Welding Titanium and Inconel?

Welding titanium and Inconel requires a tailored approach due to their unique metallurgical properties. Gas tungsten arc welding (GTAW) is a prevalent method for titanium, as it produces clean, high-quality welds with minimal contamination. When working with Inconel, both GTAW and gas metal arc welding (GMAW) are effective, but factors such as preheat and interpass temperature management become critical. For instance, Inconel 625 can experience solidification cracking if these parameters are not controlled effectively. Data suggests that maintaining a preheat temperature around 100°F can enhance the mechanical integrity of the weld.

Compatibility between welding materials also plays a crucial role in the aerospace industry. A comprehensive understanding of filler materials is essential, as improper selections can lead to compromised weld strength. An aerospace machining company focused on the fabrication of critical components may opt for ER Ti-6Al-4V as a filler for titanium, while Inconel welds might employ ERNiCrMo-3 to maintain corrosion resistance. Industry best practices recommend implementing a mechanical cleaning process before welding to minimize contamination risks, which is vital in maintaining established aerospace standards. Additionally, post-weld heat treatment can further improve the properties of welded joints, ensuring component reliability under extreme conditions.

Industry Standards and Regulations

Aerospace components must adhere to rigorous industry standards and regulations, such as those set forth by the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). These standards often dictate the material selection, testing procedures, and quality assurance measures necessary for aerospace machining, ensuring products meet specific safety requirements. For example, the aerospace industry frequently utilizes the AS9100 quality management system, which emphasizes risk management and emphasizes adherence to national and international regulations throughout the supply chain.

Compliance with standards can significantly affect the choice between titanium and Inconel for specific applications. Titanium alloys, known for their strength-to-weight ratio and corrosion resistance, often meet weight-sensitive applications as dictated by various regulations. Conversely, Inconel’s superior high-temperature performance makes it suitable for components facing extreme conditions, such as turbine blades in jet engines. Aerospace machining companies must integrate these material characteristics into their design and manufacturing processes, addressing both regulatory compliance and operational performance.

Conclusion

The choice between titanium and Inconel for aerospace components remains critical for enhancing performance and reliability. Analysis shows that titanium offers exceptional strength-to-weight ratios, ideal for weight-sensitive applications, while Inconel excels in high-temperature environments, making it suitable for components subjected to extreme heat and stress. Each material's distinct thermal and mechanical properties necessitate careful consideration during component design. In aerospace machining, selecting the most advantageous material can significantly affect durability and operational efficiency.

Companies engaged in aerospace machining are increasingly leveraging advanced techniques to optimize the fabrication processes of these materials. For instance, specific CNC aerospace machining capabilities enable the production of intricate designs that meet stringent industry standards while minimizing waste. Expertise in welding techniques tailored for each metal further reinforces the idea that an informed choice between titanium and Inconel can lead to enhanced performance and compliance with aerospace regulations. Evaluating these trade-offs effectively serves to align engineering decisions with broader manufacturing goals.